What is Variable Frequency Drive?

By K. Durgasharan, Director, Versa Drives

A Variable Frequency Drive for AC motors, also known as AC drive, is an electronic device which receives energy from a fixed frequency fixed voltage AC source (either single phase or three phase) and converts it into a variable voltage (or current), variable frequency three phase supply. This controls and enables a three-phase motor to operate at multiple speeds. Hence it comes under the category of variable speed drives.

Variable frequency drives come in a variety of configurations. At a basic level there are the single-stage frequency converter drives such as the cycloconverters and multi-stage frequency converter drives. Cycloconverters are frequency changers that convert ac input power at one frequency to output power at a different frequency with a one-stage conversion process. Cycloconvertes are usually thyristor based and used in multi-megawatt applications. Another single-stage frequency converter is the matrix converter which uses high frequency bidrectional semiconductor switches and pulse width modulation (PWM) techniques to accomplish the frequency conversion. The switches are controlled by PWM to vary to magnitude both the magnitude and frequency of the output voltage.

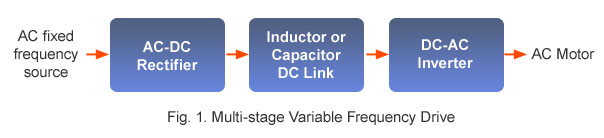

However the most commonly used VFDs are multi-stage converters. In these drives the input energy from a fixed frequency AC source (the AC mains power supply) is converted to a DC form by means of a rectifier and stored in a energy storage element in the drive. The variable voltage (or current), variable frequency output is generated from this energy reservoir. Thus there is a multi-stage AC-DC-AC conversion process. The following diagram illustrates the multi-stage energy conversion process.

The energy source element could be an inductor or a capacitor. When an inductor is used the inverter in the output is a current source and the drive is called a Current Source Inverter (CSI) drive. When the energy storage is a capacitor the output inverter is a voltage source inverter and hence the drive is called a Voltage Source Inverter (VSI) drive. The term ‘DC link’ is used to denote the energy storage element as a DC voltage across the capacitor or a DC current in an inductor is involved. VSI drives are more common than CSI drives. CSI drives are used in higher power applications.

The output inverter is usually controlled by PWM techniques to produce an output voltage or an output current of variable magnitude and variable frequency. These are termed as the PWM VSI drives and PWM CSI drives respectively.

The most commonly used VFDs are the PWM VSI drives. These are used in applications which range in power levels from a few watts to several hundreds of kilowatts. PWM VSI drives are further classified as V/F drives or vector drives based on the control technique used. V/F drives maintain a V/F ratio i.e. when the output frequency is changed the output voltage is also changed in a fixed manner. This simple technique is adequate for many applications. Certain applications such as variable torque loads (fans, centrifugal pumps) can generally be driven only by V/F drives. V/F drives are also used to drive AC motors connected in parallel. V/F drives are extensively used in energy saving applications.

Vector control drives are more sophisticated in terms of the control software and hardware they employ. They control the AC motor magnetic field’s direction and magnitude to enable instantaneous torque control. This enables vector control AC drives to be used in applications which require full torque over a wide speed range and fast torque response; an area earlier restricted to DC motors. Vector control drives coupled with PMSM and BLDC servo motors serve the precision motor control applications market.

The PWM VSI drive is a versatile motor control equipment which can be used in any application which requires variable speed. It is used in applications ranging from simple fan control to complex high performance servo drives in machine tools. Combined with an AC Induction motor or BLDC motor it forms a rugged and cost effective solution for most variable speed applications.